|

|

|

|

System Architectures > Remote I/O System

|

|

|

|

|

|

Remote I/O System

|

|

|

For different fieldbus or real-time Ethernet networks, such as Modbus, Ethernet/IP, Profinet, etc, APAX series offers different kinds of couplers for communication. Any controller or computer in the same network can access APAX I/O modules through the coupler. Not having to change I/O modules for different fieldbus or real-time Ethernet networks helps save I/O modules’ investment for future demands.

|

|

The Benefits of Remote I/O System

|

|

|

- Not only remote data acquisition I/O, but also remote controlled I/O

- Performs PLC remote I/O control capabilities through couplers with different protocols

(Modbus/TCP, Ethernet/IP, etc.)

- Configures different input types and ranges for each analog input channel, offering

great flexibility and scalability

|

|

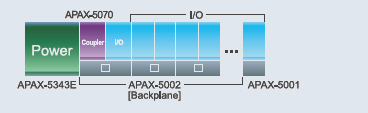

Links APAX-5000 I/O modules to different real-time Ethernet or fieldbus systems through couplers, making it a remote I/O system.

|

|

|

Target market: Remote Data Acquisition and Control

- PLC Remote I/O Modules

- Paperless Data Recorder, combining with TPC (Temperature, Pressure) (Advantage: Real-time)

|

- Market Characteristics and Requests

The PLC market is a huge market for many control and automation applications. This market is dominated by many PLC vendors like Siemens, Rockwell AB, GE Fanuc, Omron, Mitsubishi, and Modicon. These PLC suppliers define the remote I/O communication protocol (like Modbus, Profinet, Ethenrnet/IP, CANOpen, etc) to allow remote I/O devices to connect with their PLC. To expand their remote I/O communication protocol adoption, these PLC vendors open their protocols to many remote I/O device makers and communication device designers. Therefore, many automation, measurement and data logging software development companies implement these protocol drivers in their HMI/SCADA software package. Many SoftPLC software development companies also implement protocol drivers into their software package (like NI LabVIEW, KW MultiProg, and 3S-Smart Codesys). HMI/SCADA software focuses on data presentation and data logging, while SoftPLC software focuses on measurement and control tasks.

- Why APAX is suitable for this market?

APAX series' coupler products are designed for real-time data measurement and control applications. Currently, Advantech provides Modbus/TCP protocols for remote I/O applications. Advantech will release Ethernet/IP, CANOpen, and Profinet couplers in the following months. To meet different application requirements, engineers can simply select different communication couplers for various communication protocols. Regardless which communication coupler is selected, engineers can benefit from using the same I/O modules, greatly reducing I/O module stock costs. APAX couplers and I/O modules feature real-time performance and excellent flexibility. For one station, there can be up to 32 I/O modules connected. All the stations can be cascaded with daisy-chain connection, and the distance between each station can be up to 100m. All analog input and output modules provide channel-independent range configuration. It can save system costs by eliminating signal converters.

- How APAX is suitable for this market?

The APAX-5070 communication coupler series is a good solution for remote I/O applications with many different kinds of couplers. In 2010, Advantech will release Modbus/TCP, Ethernet/IP and Profinet couplers. APAX couplers with I/O modules feature more flexible topology architecture. You can use standard Ethernet switch to build a line, star or tree topology to easily extend your remote I/O network. Excellent real-time I/O bus performance and I/O modules expansion ability makes them suitable for any application.

|

|

|

|

|