|

|

|

|

System Architectures > Dual Controllers

|

|

|

|

|

|

Dual Controllers

|

|

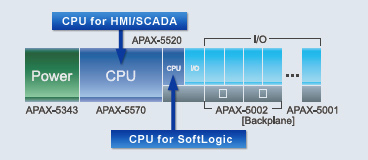

APAX-5000 series features unique system architecture, two individual controllers executing different tasks, integrated into one platform. One controller focuses on I/O control processing, while the other controller possesses high computing performance to be responsible for tasks like database, HMI/SCADA software, recipes, communication, storage, vision processing, and more.The I/O process won't be disturbed by other tasks to increase system reliability.

|

|

The Benefits of Dual Controllers

|

|

|

- Unique and reliable dual CPU architecture

- Less integrated effort on control, HMI and data analysis

- Empowers each controller with more resources to reliably execute applications

|

|

One controller concentrates on I/O processing, while another controller works on other tasks.

|

|

|

Target Market: Machine Automation

|

- Market Characteristics and Requests

In the Machine Automation market, almost every end user faces a big challenge. “Does our machine controller only provide I/O control functions? Is there any differentiate between our machine and other machine maker’s machine? “”How can we be sure our machine can produce high quality products?” “How can we easily integrate all production line controllers with motion machine & process equipment?

In the past, end users must spend a lot of time and costs to learn different systems. They need to understand motion controllers, process controllers and HMI systems, and integration is not easy. Therefore, it takes time and effort to build a complete system.

On the other hand, machine builders who are responsible for motion machines and process equipment are looking for a single solution that can combine I/O control with motion, process functionality and PC-based operator interfaces to reduce risks and service costs for integration.

- Why APAX is suitable for this market?

APAX series is one complete solution platform, designed for control and information processing applications to reduce integration cost and time. In one APAX system, there can be one, two or three controllers installed. With the same I/O modules, machine builders can design different control functionality for motion, process, batch and other customization applications. The APAX unique dual controller architecture is suitable for machine I/O control functions as well as data processing, data display, data analysis and data recording applications. One controller handles I/O control tasks, while the other handles data processing or operations. No extra wiring is needed for this architecture. Besides, engineers don’t need extra software programming to integrate the two controllers for different applications. Adapting the APAX solution, you can simply use one system (including controllers and I/O modules) for motion, batch control, data analysis and data operation functionality in your manufacturer plant, in the same programming environment.

- How APAX is suitable for this market?

APAX-5000 series offers many different kinds of dual controller architectures. For example, one WinCE controller with VC/C++ program can work with another IEC 61131-3 programmable controller. Another option is to combine one Windows XP Embedded controller with .NET program with one IEC 61131-3 programmable controller. There are at least 5 dual processor architectures users can choose.

|

|

|

|

|